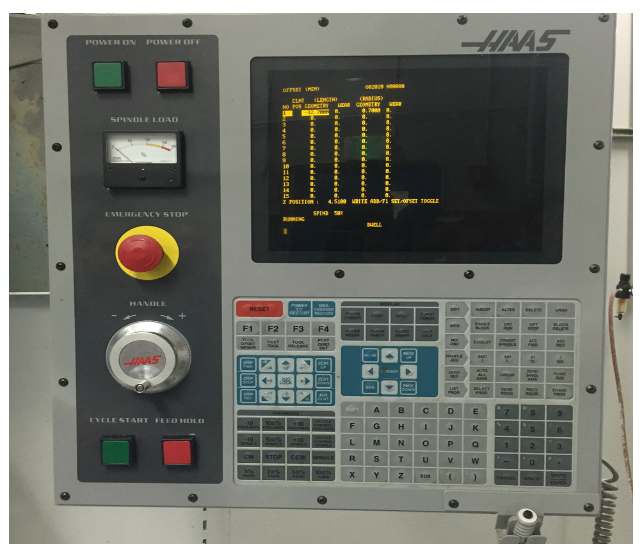

Hass Cnc Milling Machine Manuals

My boss asked me to look around for a new milling machine for the shop. This will be our only mill in the shop for general machining use, but we'd like to include 3 axis CNC. I'm looking for recommendations on brand of machine to look into, or a specific machine that anyone thinks would be ideal. It will probably be a knee-mill bridgeport clone, I'd like a 54' table. Any recommendations? What machines do you currently use and what would you recommend.

How To Program A Haas Cnc Milling Machine

Each Haas CNC machine (“Machine”) and its components (“Components”). In regards to the Haas Operator's manual, please contact us via our E-mail, pubs.

CNC machinists can freely download Haas Mill Manual from Haas website. Haas mill manual contains full cnc operating and programming details. This material is to be used as a guide to operation of the machine tool. Haas CNC Mill Operator Manual Table of Contents INTRODUCTION TO BASIC.

2002 nissan altima service manual pdf. Nissan Maxima 1994-2014 Factory Service Repair Manual PDF.

Price (within reason) is a small consideration, but if it's $20,000+- I can probably get it through. Just looking for a GOOD, Quality machine. Thanks for any help. We have three Ser 2 knee mills fitted with MIllpwr ( Acurite) controls two are 2 axis and the others are 3 axis. Another is an old servo SAM 5 bed mill refitted with the 3 axis Millpwr ( The servo control died). We are very happy with them.

Cnc Milling Machine For Sale

Easy to learn and use and they have conversational, dxf, and a limited G-code programming. I have actually done 3D work on the 3 axis machines. I takes about three hours to learn how to work them and in a month your an expert. One nice thing I like is you can go into the setup screen and change the 3 axis to a two axis control, very nice when you are just making a easy two or three parts.

Benchtop Cnc Milling Machine

The quill releases. The first Millpwr controlled mill I had is still running after 15 years. All of these controls are on good brand import mills. Kent, Acer, Acra, and the SAM 5 is a King I believe. All have power draw bars and veriable Freq.

Spindle mtr drives. Two have R8 spindles and two NTBA 40 tapers. I like the 40 tapers better.

I have retrofit mills from a 2 axis knee mill to a machining center with a 24 tool changer. My favorite all in one machine is a 3 axis bed mill with a manual quill on the head. With a Centroid control I have quit using my 2 Bridgeports. The iron is a Birmingham B3V with 40' x,20'y and 24' of z travel. I installed a readout on the quill, it is a very productive machine. The only problem I could see for a home shop is the overall height.Milltronics makes a machine like that too.

The head moves on ways for CNC action, the quill moves for manual use. R8 knee mills, and 40 taper bed mills. An uncle of mine that has been in a machine shop for the last 30 (or 40) years also mentioned the Southwest Industries Prototrack mills. They look like a good machine. One thing he really liked about them was the Z axis was a cumulative process where the head and quill both read on the readout. Also they are a much more substantial machine than a knee mill.

Otherwise he thought a series II Bridgeport might be a good all-around machine. This will be our ONLY mill in the shop, so 90% of the work done on it I will imagine will be done manually, but we were wanting CNC capabilities along with that.

Thanks for the ideas, and I think I'll look at that Prototrack more closely. An uncle of mine that has been in a machine shop for the last 30 (or 40) years also mentioned the Southwest Industries Prototrack mills. They look like a good machine. One thing he really liked about them was the Z axis was a cumulative process where the head and quill both read on the readout. Also they are a much more substantial machine than a knee mill. Otherwise he thought a series II Bridgeport might be a good all-around machine.

This will be our ONLY mill in the shop, so 90% of the work done on it I will imagine will be done manually, but we were wanting CNC capabilities along with that. Thanks for the ideas, and I think I'll look at that Prototrack more closely. I have had the TM-2 in our shop and running it for about 2 mos.

Now.not a lot of work but it does 100x as much as any bridgeport I used. It has taken some time to understand but it is going to be a great asset in the next month for an R&D project.