Yamaha Exciter Manual

This is the Highly Detailed factory service repair manual for the1988 YAMAHA EXCITER 570 SNOWMOBILE, this Service Manual has detailed illustrations as well as step by step instructions,It is 100 percents complete and intact. They are specifically written for the do-it-yourself-er as well as the experienced mechanic.1988 YAMAHA EXCITER 570 SNOWMOBILE Service Repair Workshop Manual provides step-by-step instructions based on the complete dis-assembly of the machine.

View and Download YAMAHA EXCITER owner's/operator's manual online. EXCITER Jet Boat. EXCITER Boat pdf manual download. View and Download YAMAHA EXCITER 270 owner's manual online. EXCITER 270 Jet Boat. EXCITER 270 Boat pdf manual download.

It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. Complete download comes in pdf format which can work under all PC based windows operating system and Mac also, All pages are printable. Using this repair manual is an inexpensive way to keep your vehicle working properly. Service Repair Manual Covers: General Information Periodic Inspections and Adjustments Engine Overhaul Cooling System Carburetion Power Train Chassis Electrical Appendices File Format: PDF Compatible: All Versions of Windows & Mac Language: English Requirements: Adobe PDF Reader NO waiting, Buy from responsible seller and get INSTANT DOWNLOAD, Without wasting your hard-owned money on uncertainty or surprise! All pages are is great to have1988 YAMAHA EXCITER 570 SNOWMOBILE Service Repair Workshop Manual. Looking for some other Service Repair Manual,please check: Thanks for visiting!

1988 Yamaha Exciter 570 Snowmobile Service Repair Manual. 1. INDEX GENERAL INFORMATION PERIODIC INSPECTIONS AND ADJUSTMENTS ENGINE OVERHAUL COOLING SYSTEM CARBURETION POWER TRAIN CHASSIS ELECTRICAL APPENDICES '-ENG CHAS III , APPX. CHAPTER 1. GENERAL INFORMATION MACHINE IDENTIFICATION.

1-1 FRAME SERIAL NUMBER. 1-1 ENGINE SERIAL NUMBER. 1-1 STORAGE.

1-2 PRE-SEASON PREPARATION. 1-2 IMPORTANT INFORMATION. 1-3 NO FLAME SOURCES.

1-3 WASHING AND CLEANING. 1-3 RIGHT TOOLS. 1-3 MAKING IT NEAT. 1-3 TIGHTENING TORQUE.

1-3 ALL REPLACEMENT PARTS. 1-4 GASKETS, OIL SEALS, AND O-RINGS. 1-4 LOCK WASHERS/PLATES AND COTTER PINS.

1-4 BEARINGS AND OIL SEALS. 1-4 Cl RCLIPS. 1-5 NOTES ON DISASSEMBLY AND ASSEMBLY. 1-5 SPECIAL TOOLS. 1-6 FOR TUNE UP. 1-6 FOR ENGINE SERVICE.

1-6 FOR POWER TRAIN SERViCE. 1-7 FOR ELECTRICAL SERVICE. 1-8. 11 GENERAL INFORMATION MACHINE IDENTIFICATION FRAME SERIAL NUMBER The frame serial number CD is located on the right-hand side of the frame (just below the front of the seat). ENGINE SERIAL NUMBER The engine serial number CD is located on the right-hand side of the crankcase.

NOTE: The first three digits of these numbers are for model identifications; the remaining digits are the unit production number. Starting Serial Number 82M000101 NOTE: Designs and specifications are subject to change without notice.

STORAGE/PRE-SEASON PREPARATION III STORAGE If a snowmobile will not be used for several months, it should be stored in a proper place so that both the engine and the track are not damaged. Completely drain the fuel tank, and disconnect the fuel line from the carburetor. With the engine running at idle, squirt oil into the carburetor until the engine dies. This will distribute oil evenly throughout the engine, and protect it against rust. Disassemble the suspension, clean and grease all parts, and reassemble the suspension. Lightly coat all shafts and axles with grease.

Oil all fittings and cable controls with a lightly oiled cloth. Loosen the track. Block the chassis so that the track is off the floor. Protect the snowmobile with a covering.

PRE-SEASON PREPARATION Perform the predelivery service as described in the predelivery check list before operating any snowmobile that has been stored for several months. (Refer to CHAPTER 2. 'PERIODIC MAINTENANCE TABLE', page 2-1.) 1-2. 1-3 IMPORTANT INFORMATION IMPORTANT INFORMATION PREPARATION FOR REMOVAL AND DIS- ASSEMBLY 1. Remove all dirt, mud, dust, and foreign material before removal and disassembly.

While cleaning, take care to protect the electrical parts, such as relays, switches, motor, resistors, controllers, etc., from high pressure water splashes. Use proper tools and cleaning equipment. Refer to 'SPECIAL TOOLS'. When disassembling the machine, keep mated parts together. This includes gears, cylinders, pistons, and other mated parts that have been 'mated' through normal wear. Mated parts must be reused as an assembly or replaced.

During the machines disassembly, clean all parts and place them in trays in the order of disassembly. This will speed up assembly time and help assure that all parts are correctly reinstalled. Keep away from fire. Be sure to keep to tightening torque specifi- cations. When tightening bolts, nuts, and screws, start with a larger-diameter one and from an inner-positioned one to an outer- positioned one in a criss-cross pattern. IMPORTANTlNFORMATION 1tm:I-1 ALL REPLACEMENT PARTS 300-000 300-002 300-003 1. We recommend to use Yamaha genuine parts for all replacements.

Use oil and/or grease recommended by Yamaha for assembly and adjustment. GASKETS, OIL SEALS, AND a-RINGS 1. All gaskets, seals, and a-rings should be re- placed when an engine is overhauled. All gasket surfaces, oil seal lips, and a-rings must be cleaned. Properly oil all mating parts and bearings during reassembly.

(& mine!) • Excellent! 2010 yamaha v-star 250 owners manuel. Will definitely recommend to friends. Couldn't find it anywhere else!

Apply grease to the oil seal lips. LOCK WASHERS/PLATES AND COTTER PINS 1. All lock washers/plates CD and cotter pins must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or nut flat(s) after the bolt or nut has been pro- perly tightened. BEARINGS AND OIL SEALS 1. Install the bearing(s) CD and oil seaJ(s) ® with their manufacturer's marks or numbers facing outward. (In other words, the stamped letters must be on the side exposed to view.) When installing oil seaJ(s), apply a light coating of light-weight lithium base grease to the seallip(s).

Oil the bearings libe- rally when installing. Do not use compressed air to spin the bearings dry. This causes damage to the bearing surfaces. '-4 D. SPECIAL TOOLS 300-001 1-5 CIRCLlPS 1.

All circlips should be inspected carefully be- fore reassembly. Always replace piston pin clips after one use.

Replace distorted cir- clips. When installing a circlip CD, make sure that the sharp edged corner 00 is positioned opposite to the thrust @ it receives. See the sectional view. @Shaft SPECIAL TOOLS The proper special tools are necessary for com- plete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or impro- vised techniques. FOR TUNE UP 1. Vacuum Gauge PIN Y U-08030 This gauge is used for carburetor synchroniza- tion.

Sheave Gauge PIN YS-91 047 This gauge is used for sheave distance and offset adjustment. Dial Gauge PIN Y U-03097 This gauge is used for ignition timing adjust- ment. SPECIAL TOOLS 4.

Dial Gauge Stand Set PIN YU-01256 These tools are used for ignition timing adjust- ment. FOR ENGINE SERVICE 1. Universal Clutch Holder PIN YM-91042 This tool is used to hold starter pulley.

Piston Pin Puller PIN YU-01304 This tool is used to remove piston pin. Universal Rotor Holder PIN YU-01235 This tool is used to hold CD I magneto. Rotor Puller PIN YU-33270 This tool is used to remove COl magneto. 1-6.

SPECIAL TOOLS 1-7 5 Cooling System Tester PIN YU-22460-01 This tester is used for checking cooling system. FOR POWER TRAIN SERVICE 1. Primary Sheave Holder PIN YS-01880 This tool is used to hold primary sheave. Primary Shave Puller PIN YS-01882-A This tool is used for removing primary sheave.

Sheave Compressor PIN YS-28891 This tool is used for disassembling and assembl- ing sheave. Clutch Spider Separator PIN YS-28890-A These tools are used for disassembling and assembling primary sheave. SPECIAL TOOLS IIJ:I- 5. Clutch Separator Adapter PIN YS-34480 This tool is used for disassembling and assembl- ing primary sheave.

Track Clip Installer PIN YS-91045 This tool is used for installing the track clip. FOR ELECTRICAL SERVICE 1.

Pocket Tester PIN YU-03112 This instrument is necessary for checking the electrical components. Electro Tester PIN Y U-33260 This instrument is invaluable for checking the electrical system. 1-8. CHAPTER 2.

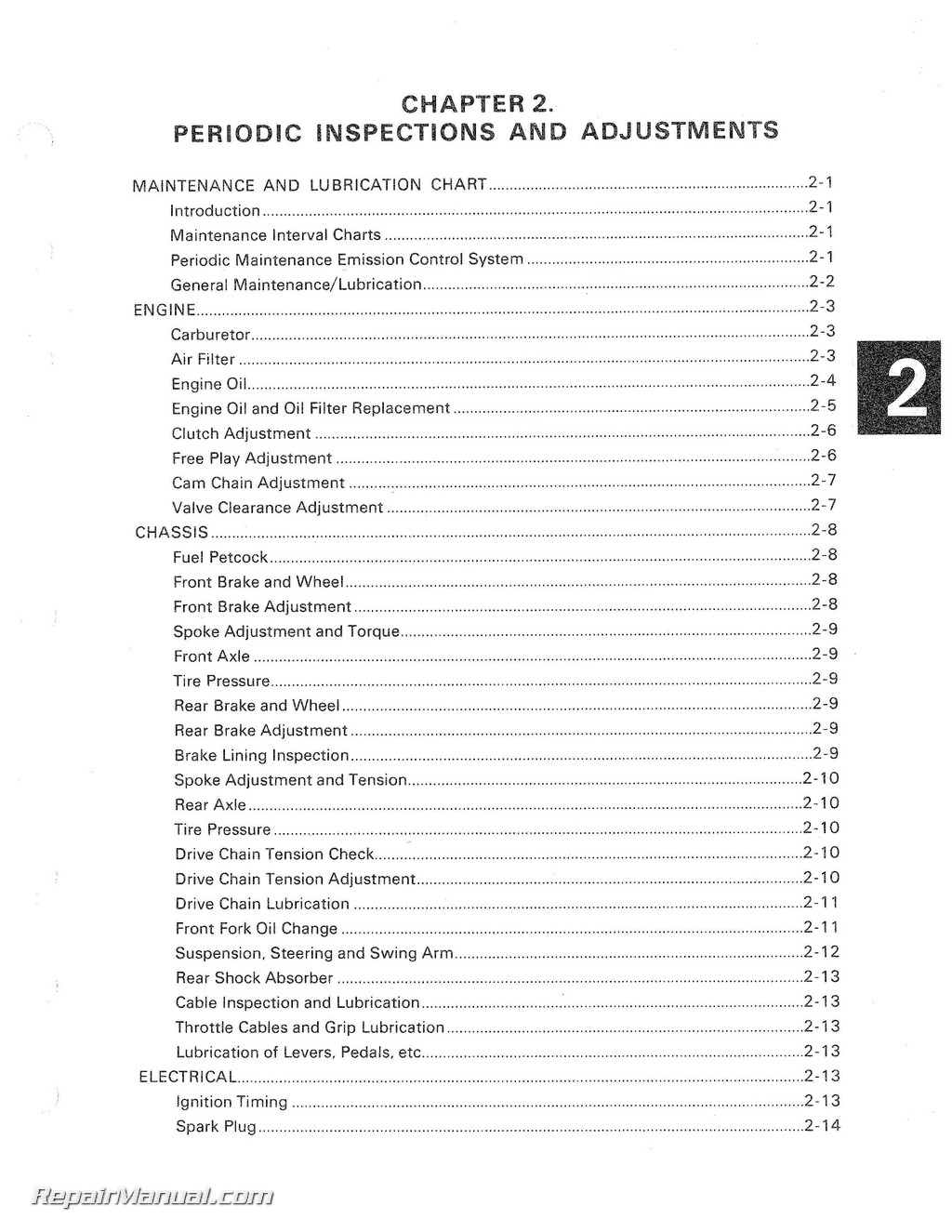

PERIODIC INSPECTIONS AND ADJUSTMENTS INTRODUCTION. 2-1 PERIODIC MAINTENANCE TABLE., '. 2-1 LUBRICATION INTERVALS. 2-3 COWLS, COVERS, SEAT AND HANDLEBAR. 2-4 SHROUD OPENING. 2-4 SIDE COWL.

2-4 SEAT. 2-5 HANDLEBAR COVER, HEADLIGHT AND METER ASSEMBLY. 2-6 HANDLEBAR.

2-7 COVERS. 2-9 ENGINE. 2-12 ENGINE OIL LEVEL INSPECTION. 2-12 COOLANT LEVEL INSPECTION. 2-12 COOLANT REPLACEMENT.

2-13 COOLING SYSTEM INSPECTION. 2-17 FUEL LINE INSPECTION. 2-18 ENGINE OIL LINE INSPECTION.

2-18 ENGINE IDLE SPEED ADJUSTMENT. 2-18 THROTTLE CABLE FREE PLAY ADJUSTMENT.

2-19 CARBURETOR SYNCHRONIZATION. 2-20 STARTER CABLE ADJUSTMENT. 2-22 DECOMPRESSION CABLE ADJUSTMENT. 2-23 OIL PUMP CABLE FREE PLAY ADJUSTMENT. 2-24 OIL PUMP STROKE ADJUSTMENT. 2-25 OIL PUMP AIR BLEEDING. 2-30 OIL FILTER INSPECTION.

2-34 FUEL FILTER INSPECTION. 2-35 FUEL PUMP OPERATION CHECK. 2-36 WATER PUMP DRIVE BELT TENSION ADJUSTMENT. 2-40 POWER TRAIN. 241 DRIVE VBELT INSPECTION. 241 SHEAVE DISTANCE AND OFFSET ADJUSTMENT. 242 DRIVE CHAIN HOUSING OIL LEVEL INSPECTION.

2-46 DRIVE CHAIN HOUSING OIL REPLACEMENT. 2-47 DRIVE CHAIN SLACK ADJUSTMENT. 248 BRAKE PAD INSPECTION. 250 BRAKE ADJUSTMENT. 251 TRACK TENSION ADJUSTMENT. 253. CHASSIS.

2-55 SKI ADJUSTMENT. 2-55 BRAKE CABLE END LUBRICATION. 2-57 FRONT SUSPENSION LUBRICATION. 2-57 STABILIZER SLlDER MAINTENANCE.

1980 Yamaha 250 Exciter Manual

2-57 SLIDE RUNNER INSPECTION. 2-58 ELECTRICAL. 2-58 SPARK PLUG INSPECTION. 2-58 IGNITION TIMING ADJUSTMENT. 2-59 HEADLIGHT BULB REPLACEMENT.

2-61 HEADLIGHT BEAM ADJUSTMENT. 2-62 TAIL/BRAKE LIGHT BULB REPLACEMENT. 2-63 METER LIGHT REPLACEMENT. 2-63 TUNING. 2-64 CARBURETOR TUNING. 2-64 CLUTCH TUNING.

2-72 GEARING SELECTION. 2-73 SLIDE RAIL SUSPENSION TUNING. 2-75 HIGH ALTITUDE TUNING. 2-77. I IQ IINTRODUCTION/PERIODIC MAINTENANCE TABLE PERIODIC INSPECTIONS AND ADJUSTMENTS INTRODUCTION This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly overhaul work will be greatly reduced.

This information applies to vehicles already in service as well as new vehicles that are being prepared for sale. All service technicians should be familiar with this entire chapter. PERIODIC MAINTENANCE TABLE Every Check point 20 hrs.

Yamaha Exciter 220 Manual

Yamaha Jet Boat Manuals (Boats you sit in, not on) This is the BEST, most complete workshop repair and maintenance manual available anywhere on the internet! All of the manual listed below are full factory service manuals with hundreds of pages containing step by step instructions, full wiring diagrams and detailed illustrations and photos on how to repair, rebuild or maintain virtually anything to your Yamaha Jet Boat.